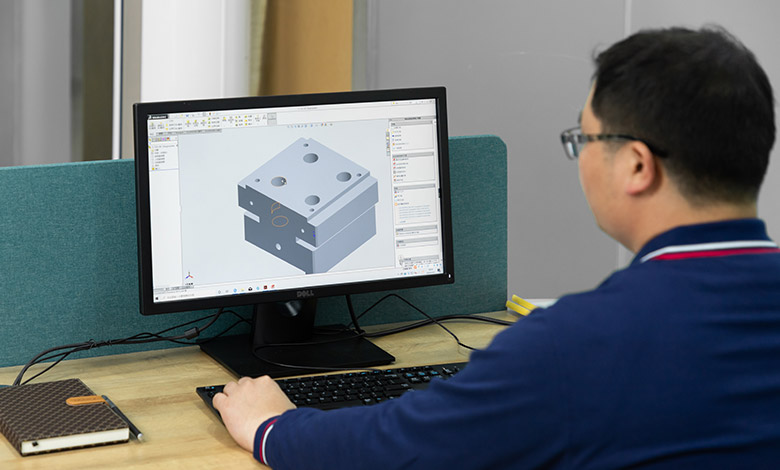

Upload Your Design

Both 2d and 3d drawings in CAD or CAM formats can provide us with great info and clear instructions.

Winmi helps maximize your ROI by providing you with fast and cost-saving services while meeting your stringent standards.

The tightest tolerance of 0.005mm can be minimized to 0.0001mm after surface grinding.

30+ types of materials, 90+ machines, 50+ workers plus a reliable, integrated supply chain serve all your needs.

Full inspections and the quality control process ensure your parts are made for outstanding performance.

Large or small workpieces of 1–2000mm in length and width can get into processing. Winmi also offers surface grinding and assembly services upon request.

3-axis and 4-axis machining move materials to create simple features accurately on the flat surface of the fixed workpieces.

Lathes and mill-turning centers turn the workpiece to produce cylindrical features with fixed cutters and center drills.

Wire EDM produces intricate internal geometries more precisely with the tightest precision and no need for post-processing.

Within 6 steps, the parts from your small-quantity parts as well as medium and large volume orders are ready to be processed at a low cost and shipped fast.

Both 2d and 3d drawings in CAD or CAM formats can provide us with great info and clear instructions.

Do not know which to choose among CNC milling, CNC turning and wire EDM? Winmi’s experienced engineers are here to help.

Winmi offers you 30+ types of engineering-grade materials from assured sources to make your high-performing precision parts.

| Aluminum | Stainless Steel | Other Steel | Brass | Copper | Taitanium | Plastics |

| Aluminum6082 (3.2315) | Steel Stainless 304(1.4301) | SS400(1.0037) | BrassC3560/2.0331 | C1020/2.0040 | Titan Grade 5(3.7165) | PVC |

| Aluminum6061(3.3206) | Steel Stainless 303(1.4305) | 1020(1.1151) | 59BrassC2800/2.0360 | SF-Cu /C1100 | Titan Grade 2(3.7164) | PP |

| Aluminum6063 (3.1645) | Steel Stainless 316 ( 1.4401) | 1045(1.1191) | H65Brass CuZn39PB3/2.0401 | C5210/2.1030 | 3.7134 | PC |

| Aluminum5052 (3.3523) | Steel Stainless 316L (1.4404) | 40Cr/1.7035 | C5191/5190/2.1020 | T-TU2 | PE | |

| Aluminum5183( 3.3547) | Steel stainless 420J2 (1.4034) | 4140(1.7225) | C6280/6300/2.0966 | T-V13CA | Polymethyl methacrylate – acrylic(PMMA – Acrylic) | |

| Aluminum5082 (3.3547) | Steel – Stainless 440 (1.4112) | 12L13(1.0718) | Ti-6Al-6V-2Sn | DERLIN | ||

| Aluminum2024 (3.3535) | Steel – Stainless 17-4PH (1.4542) | 38CrMoAL(1.8509) | ABS/Acrylonitrile Butadiene styrene | |||

| Aluminum7075(3.4365) | Steel – Stainless 430F (1.4104) | SK3(1.1645) | PTFE | |||

| O1(1.2510) | BAKELITE | |||||

| O2(1.2842) | Polyether ether ketone (PEEK) | |||||

| P20(1.2311) | PA6 + 30% GF | |||||

| D2(1.2379) | PA66 + 30% GF | |||||

| A2(1.2363) | Nylon 6 | |||||

| E52100(1.3505) | Polycarbonate + 30% Glass fill(PC + 30 % GF) | |||||

| High-density polyethylene(HDPE, PEHD) | ||||||

Winmi applies rigid inspections to its processing, from raw material inspections to final quality control. We take quality as the priority. In case of any quality issues after you receive your precision parts, Winmi will re-make them for you without charges.

Harden your parts, change the surface roughness, or make your parts resistant to oxygen and durable under extreme conditions.

Materials. Finishing. Quality Assurance. Winmi’s CNC machining service is ready to take all your needs into account.